Contract manufacturing

Partner for development of individual parts & series up to production

Partner for development of individual parts & series up to production

Modern production facilities and versatile machining processes are at your disposal. Whether it’s a single piece or a series of parts, thanks to our great flexibility we can supply you with flawless products within a short period of time, including partial assembly and surface treatments of all kind.

An experienced team will be happy to take care of your enquiries, such as functional models, prototypes, individual parts or series production with a framework agreement. INDUCTA AG has a lot of know-how to offer in the processing of entire projects, including assembly work. In the sector of welding and painting, our specialists are at your service with modern equipment.

We are open to all material groups and have high quality standards, whereby we are optimally supported by a large supplier network.

IBARMIA ZVH 48 multiprocess (X=3000; Y=1000; Z=900mm).

The milling/turning centre has a 5-axis simultaneous machining with ø800mm rotary table (machining up to ø1100mm is possible).

Victor Taichung Vturn II-16 with LNS bar feeder and driven tools. For small to medium workpieces from bar (spindle aperture ø40mm), alternatively with three-jaw chuck up to approx. ø100mm.

WEILER E35 – cycle controlled. For slightly larger workpieces up to ø310mm.

MATEC 30HV/K with robot and 24-hour production (X=1500; Y=800; Z=1100mm) with a 5-axis simultaneous machining and a rotary table of ø630mm. Automation by Cellro, total number of pallets: 40 pieces.

5-axis MATEC 30HV/K (X=1500; Y=800; Z=1100mm) 3-axis AXYLE V7 (X=1200; Y=730; Z=650mm) 3-axis Hurco (X=760; Y=508; Z=610mm) with 4th axis

With our vacuum plates we also offer various sheet of metal and plastic processing.

Our machine park also includes a wide range of conventional machines:

In-house, we are equipped with a very flexible paint booth. Whether small parts or larger workpieces, thanks to the 3x5m area, we are well equipped for many jobs. We work with industrial and car paints: thus, a processing with all available RAL, NCS and Pantone colours is possible, alternatively, a tinting according to sample can be implemented without any problems.

The clear varnishing of aluminium is one of our specialities.

We carry out general locksmith and metal construction work. We specialise in the manufacture of complex aluminium, steel and chrome steel housings (2-3mm sheet metal). The welding processes MAG and TIG as well as stud welding are used. Material cutting up to 4m is possible as well as surface treatment with glass bead blasting.

The welding and milling/turning processes can be combined directly in-house. A subsequent lacquering completes your product.

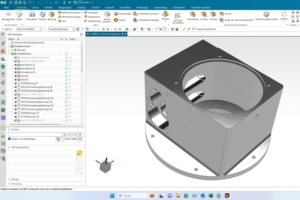

Our engineering department with 3 NX CAD workstations is happy to support you in the development and design of your parts and products. We have a state-of-the-art feature CAM for programming our CNC machines. We are able to produce prototypes and individual parts in 3D.

Our engineering department with 3 NX CAD workstations is happy to support you in the development and design of your parts and products. We have a state-of-the-art feature CAM for programming our CNC machines. We are able to produce prototypes and individual parts in 3D.

Just ask us!

Do you have questions about our possibilities? An idea that you would like to implement?

We will produce your perfect clock so time does not stand still.